About us

BAMBARRIER is a leading global manufacturer of industrial impact-safety barriers. The company designs, manufactures, and installs advanced solutions that protect people, infrastructure, and assets in industrial environments. BAMBARRIER specializes in engineered safety barriers designed to withstand repeated vehicle impacts without damaging the floor or anchoring surface.

BAMBARRIER operates across Europe through an established commercial network covering Italy, Germany, France, Spain, Portugal, The Netherlands, Denmark, Estonia, Latvia, Lithuania, Austria, Poland, Hungary, Romania, Slovenia, Slovakia, and the Czech Republic. The company's headquarters, Development Center, and certified testing facilities are located in the Czech Republic.

EXPERT TEAM FOR PIONEERING STANDARDS

BAMBARRIER's executive and technical team is composed of experienced field engineers and safety consultants with more than a decade of direct involvement in the industrial impact-protection sector. The team has actively contributed to the development of key European safety standards, including:

- BSI PAS 13:2017 – British standard for industrial safety barriers

- UNI 11886 – Italian standard for industrial impact-protection systems

This expertise ensures that BAMBARRIER solutions consistently comply with — and often exceed — applicable international safety standards, delivering regulatory confidence and long-term performance.

Products with TÜV SÜD certification, meet BSI - PAS13 and UNI 11886

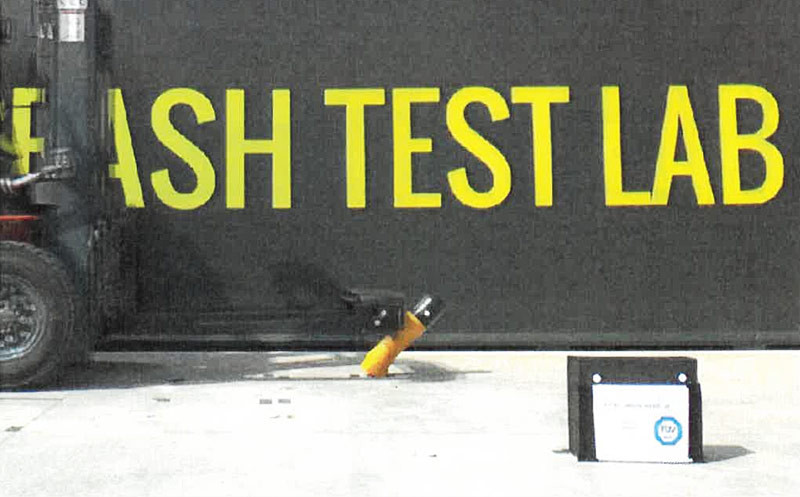

CRASH TEST LAB - thorough crash tests verified by leading certification body TÜV SÜD

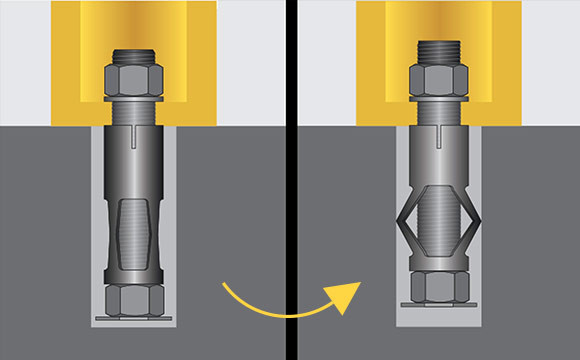

Certified anchoring system ROOTLOCK®

Designed for unparalleled floor safety and stability. More about the system

High-tech industrial polymer FLEXAFE™

A material designed to absorb and mitigate high-impact forces.

Smart security solutions

Integration of IoT technology for real-time access monitoring and alarms.

Targeted innovation

Emphasis on continuous research and technological development.

BAMBARRIER R&D Center – Czech Republic

The BAMBARRIER R&D Center represents the core of the company's innovation, engineering, and quality assurance. It is where the complete cycle - from concept development to production - of impact-safety products takes place.

Key activities include:

- Research & Development – Design of new generations of safety barriers and bollards

- Product Testing – Extensive mechanical and impact testing under the strictest conditions

- TÜV Certification – Product certification performed by accredited TÜV bodies

- Manufacturing – Modern production lines for bollards and safety barriers

- Quality Control – Independent inspection and initial validation of production quality programs

Located in Hlinsko (CZ), the R&D Center ensures that every BAMBARRIER product meets the highest international standards of quality, safety, and reliability before market release.

ENGINEERING IMPACT SAFETY — NOT "JUST PLASTIC"

Designing an effective impact-safety barrier is not a matter of shaping plastic. It requires solving complex problems in physics, mechanics, and mathematics, from concept design and material behavior to impact testing, anchoring, installation, and long-term warranty performance.

When a vehicle hits a barrier, it releases energy comparable to an explosion:

Kinetic Energy = ½ · m · v²

where m is mass (kg) and v is speed.

For this reason, BAMBARRIER evaluates barrier performance in Joules.

At the moment of impact, forces propagate unpredictably in multiple directions, making controlled energy absorption a complex engineering challenge.

The BAMBARRIER solution

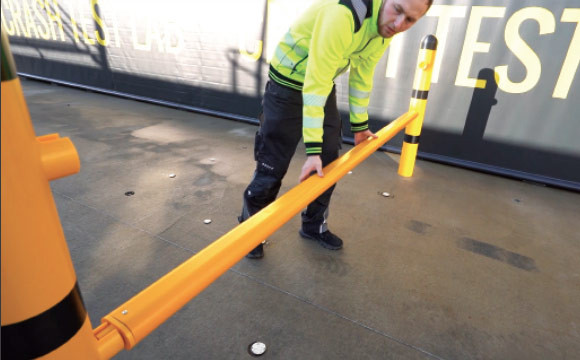

BAMBARRIER delivers impact-resistant safety barriers and guardrails engineered to absorb high-energy impacts repeatedly without damaging the floor.

Their compact design minimizes space occupancy while maximizing protection, allowing safer vehicle–pedestrian coexistence in demanding industrial environments.

BAMBARRIER's commitment is clear:

reliable engineering, proven safety, and long-term protection.

The company provides free on-site safety consultations and offers long-term warranties on both products and installation, ensuring measurable value and confidence for its customers.